-

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing

JDB Solid-lubricating Bearing JEFW Wear-Resistant Oilless Guide Flange Solid-Lubricating Bearing -

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing

JDB Solid-lubricating Bearing JPBW, JPBF Maintenance-Free Oilless Solid-lubricating Bearing -

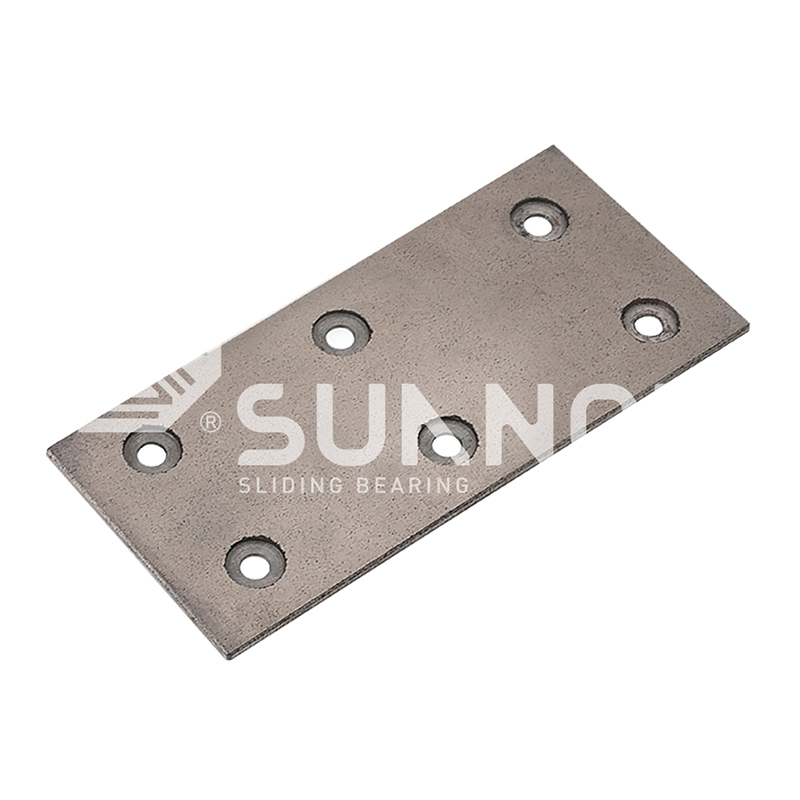

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface -

-

-

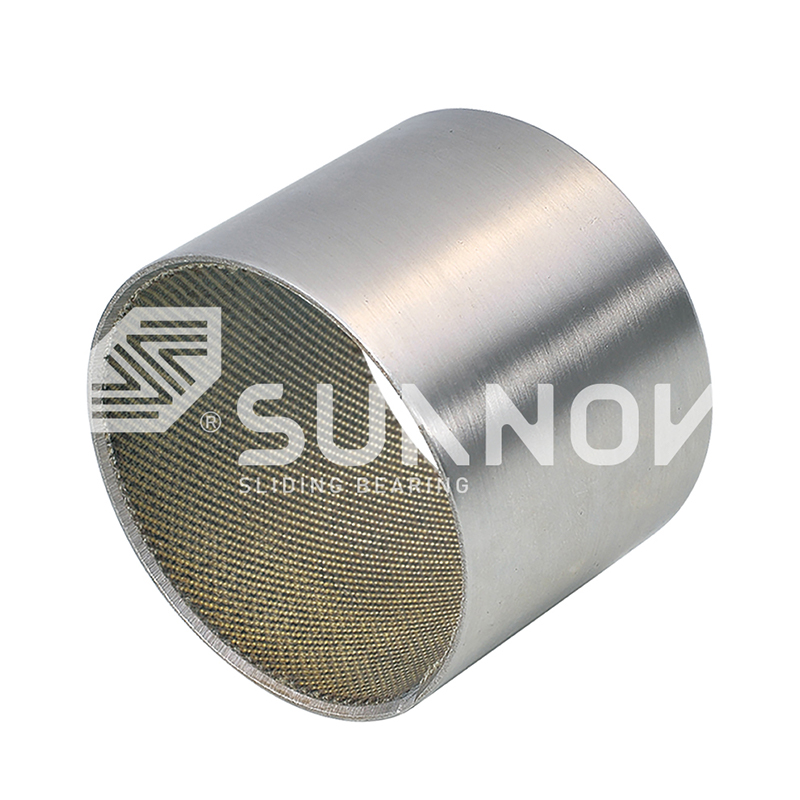

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery

SF-2 Boundary Lubricating Bearing SF-2Y Boundary Self-lubricating Bearing - Low Friction Dry Lubricant Bushings for Industrial Machinery -

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction -

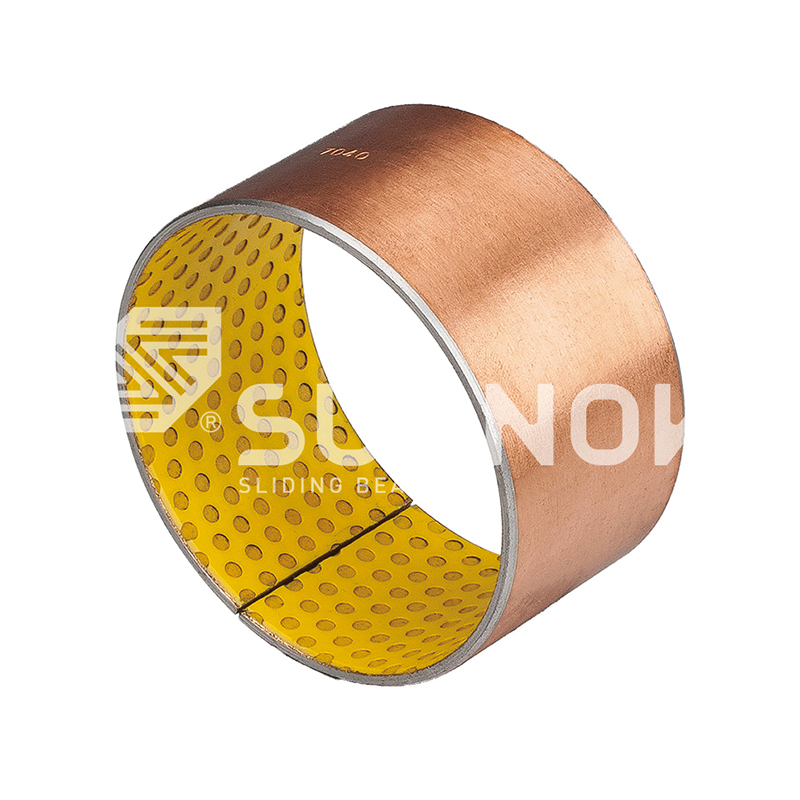

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

Working principle and industrial application analysis of JDB solid lubricating bearings

Industry News-1. What is JDB solid lubricating bearing?

JDB solid lubricating bearings (JDB Solid-Lubricating Bearing) combine the advantages of metal substrate and solid lubricant. JDB bearings usually use high-strength metal materials (such as copper alloys, steel, etc.) as the matrix, and embed solid lubricants (such as graphite, molybdenum disulfide, etc.) on the bearing surface, thereby ensuring the load-bearing capacity while improving the lubrication effect. This design not only reduces friction and wear, but also greatly improves the service life of the bearing in an oil-free environment.

2. Main features of JDB solid lubricating bearings

Self-lubricating performance: Since the bearing is embedded with solid lubricants, it can operate in an oil-free or low-oil environment, especially suitable for working conditions where maintenance cannot be performed for a long time or lubrication conditions are difficult.

High load-bearing capacity: The metal matrix of JDB bearings has high strength and wear resistance, suitable for high load and impact load occasions, and is widely used in heavy machinery.

High temperature and corrosion resistance: Embedded solid lubricants usually have good high temperature resistance, while the metal matrix can choose corrosion-resistant materials, so it has a good application effect in high temperature or corrosive media.

Low friction coefficient: Solid lubricants reduce the friction coefficient, which can effectively reduce energy loss and equipment noise, improve operating efficiency and environmental friendliness.

Good dimensional stability: JDB bearings are not easy to deform during use, have good dimensional stability, and are suitable for application in precision machinery.

3. Working principle of JDB solid lubricant bearings

The working principle of JDB solid lubricant bearings is to support the load through the metal matrix, while releasing solid lubricants during the friction process to form a lubricating film on the friction surface. This not only reduces the friction and wear of the bearing, but also effectively avoids wear and equipment failure caused by insufficient oil lubrication. Over time, the friction surface of the solid lubricant will gradually wear, but because it is evenly distributed on the bearing surface, it can continue to provide lubrication.

4. Application fields of JDB solid lubricant bearings

Due to its excellent self-lubricating performance and high temperature resistance, corrosion resistance, and heavy load resistance, JDB solid lubricant bearings are widely used in many fields:

Metallurgical equipment: JDB bearings can be used in high temperature, high pressure and heavy load parts of steel manufacturing equipment, such as continuous casting machines, rolling mills and other equipment, to reduce maintenance frequency and improve production efficiency.

Mining and heavy machinery: In mining equipment, loaders, excavators and other heavy machinery, JDB bearings can effectively improve equipment durability due to their good load-bearing performance and wear resistance.

Engineering machinery: Used in equipment working in various harsh environments such as bridge lifting equipment and construction machinery, JDB bearings can reduce equipment maintenance requirements and reduce downtime costs.

Automobile and transportation equipment: In some transmission systems that require long-term stable operation, JDB bearings provide excellent wear resistance and low friction performance, extending the life of the equipment.

Water conservancy and wind power equipment: In some areas that are difficult to maintain or difficult to refuel, such as turbines, wind turbines, etc., the solid lubrication characteristics of JDB bearings can achieve maintenance-free operation.

5. Advantages and limitations of JDB solid lubricant bearings

Advantages:

Low maintenance cost: No frequent refueling or maintenance is required, suitable for equipment that works continuously for a long time.

Long life: Solid lubricant materials reduce bearing wear and greatly extend the service life.

Environmental protection: Oil-free lubrication reduces the risk of oil contamination and is environmentally friendly.

Limitations:

Relatively high price: JDB bearings have a high production cost, so the purchase cost may be higher than traditional lubricated bearings.

Applicability restrictions: In some ultra-high speed applications, JDB bearings may not be as effective as traditional oil-lubricated bearings.