-

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing -

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing -

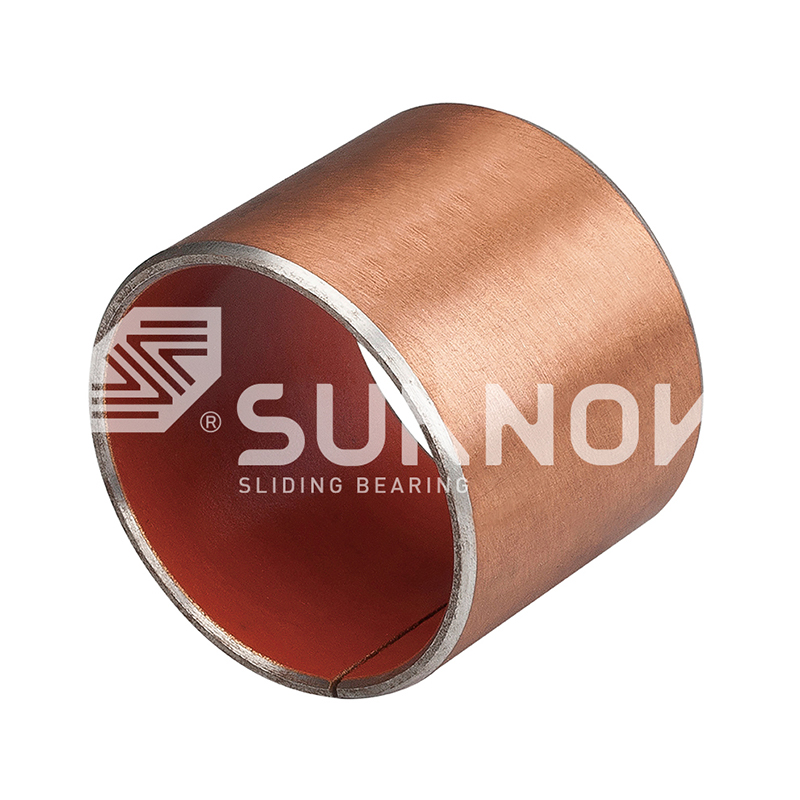

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush

SF-1 Oilless Bearing Maintenance-Free SF-1W Wall Wrapped Lead-Free Bronze Bearing Oilless Bearing Bush -

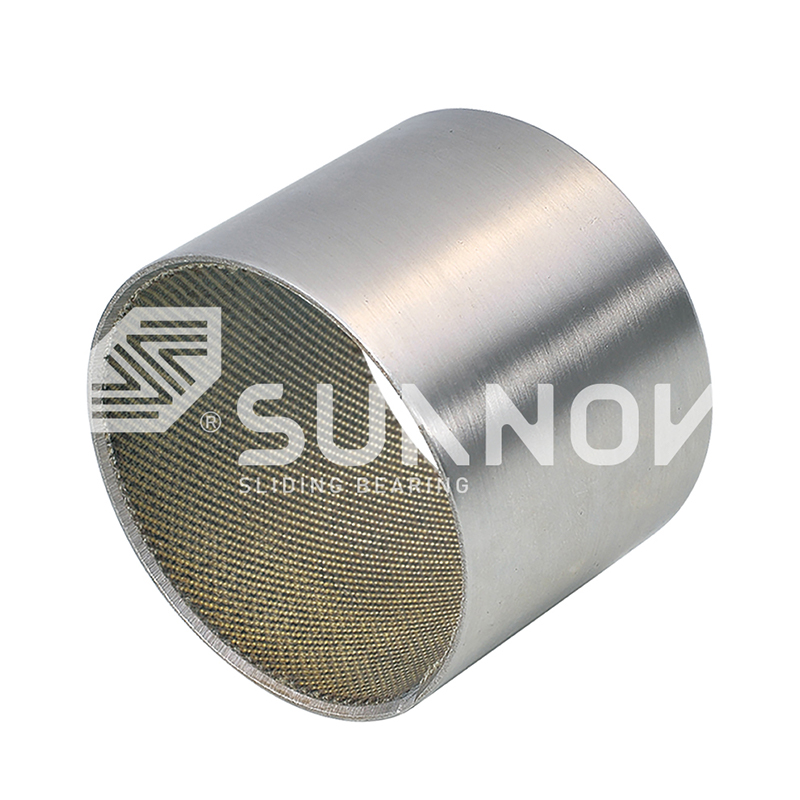

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

-

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing

SF-1 Oilless Bearing SF-1 WC Standard Metric Thrust Washer | Low Friction, High Load Bearing -

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery -

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

How does the high load-bearing capacity of SF-1 oil-free bearings change the design of automobile suspension systems?

Industry News-The high load-bearing capacity of SF-1 oil-free bearings has brought significant changes to the design of automobile suspension systems, which is mainly reflected in improving system reliability, reducing maintenance costs and improving overall performance.

1. Enhance the durability and reliability of the suspension system

The automobile suspension system bears the weight of the vehicle and road impact. Especially in bumpy or harsh road conditions, the bearings must withstand huge impact forces and loads. SF-1 oil-free bearings, with their excellent high load-bearing capacity, can effectively support suspension components under these conditions, reducing deformation and wear, thus improving the overall durability of the suspension system. The independent casting and multi-layer composite material process adopted by Zhejiang Shuangnuo ensures the material strength of the SF-1 bearing, making its application in automobile suspension systems more reliable, especially under long-term and high-intensity use environments.

2. Reduce lubrication requirements and reduce maintenance costs

Traditional automobile suspension systems require regular lubrication and maintenance to keep them running smoothly, while SF-1 oil-free bearings have self-lubricating properties and can automatically release solid lubricants during work, reducing dependence on external lubricants. This not only reduces maintenance frequency and costs, but also improves the long-term operational stability of the suspension system. During the product production process, Zhejiang Shuangnuo ensures the wear resistance and lubrication properties of bearing materials through strict material testing and spectrometer analysis, which is crucial to improving the maintenance-free performance of automobile suspension systems.

3. Impact resistance improves comfort and safety

Suspension systems are designed not only to handle loads, but also to withstand the impact of road impacts on the vehicle. SF-1 oil-free bearings have excellent impact resistance thanks to their multi-layer composite structure, especially the extremely strong steel-based material and the wear-resistant PTFE surface layer. This means that when encountering uneven road surfaces or sudden external impacts, the bearings can effectively absorb and disperse the impact, reducing damage to other suspension components, thus improving the smoothness and comfort of the vehicle. In addition, Zhejiang Shuangnuo's products adopt advanced CNC processing technology to ensure bearing precision and further enhance the safety of the suspension system.

4. Improve load capacity and optimize suspension design

Modern cars, especially SUVs and heavy-duty vehicles, need to withstand higher loads while maintaining comfort. The high load capacity of SF-1 oil-free bearings allows the suspension system to support larger loads without increasing size or weight, thus optimizing the overall design. This not only improves vehicle performance but also provides automotive designers with more design flexibility. Zhejiang Shuangnuo can customize SF-1 bearings of different materials and specifications according to customer needs through centrifugal casting, continuous casting and other processes, providing more possibilities for the design of automobile suspension systems.

5. Environmental protection and sustainability

As the automotive industry becomes increasingly strict with environmental standards, reducing the use of lubricants has become an important goal. The self-lubricating characteristics of SF-1 oil-free bearings not only reduce the consumption of lubricating oil, but also avoid environmental pollution caused by lubricating oil leakage. Zhejiang Shuangnuo's full-process quality control ensures product stability and environmental protection, complying with the green production requirements of the automotive industry.