-

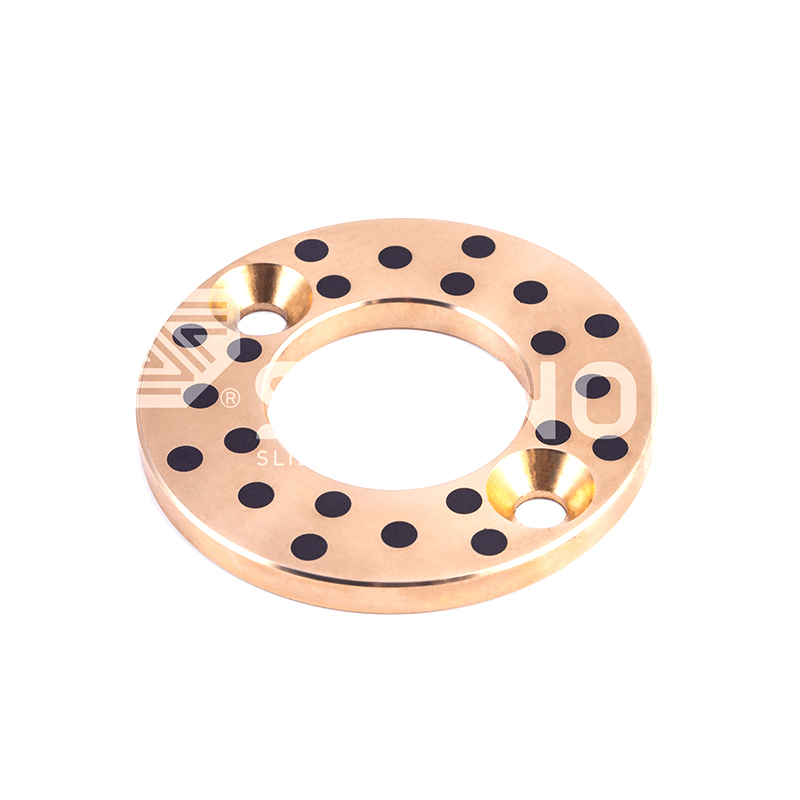

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing -

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing

JDB Solid-lubricating Bearing Maintenance-Free With Collar Brass Din9834 Oilless Guide Bushing Bearing -

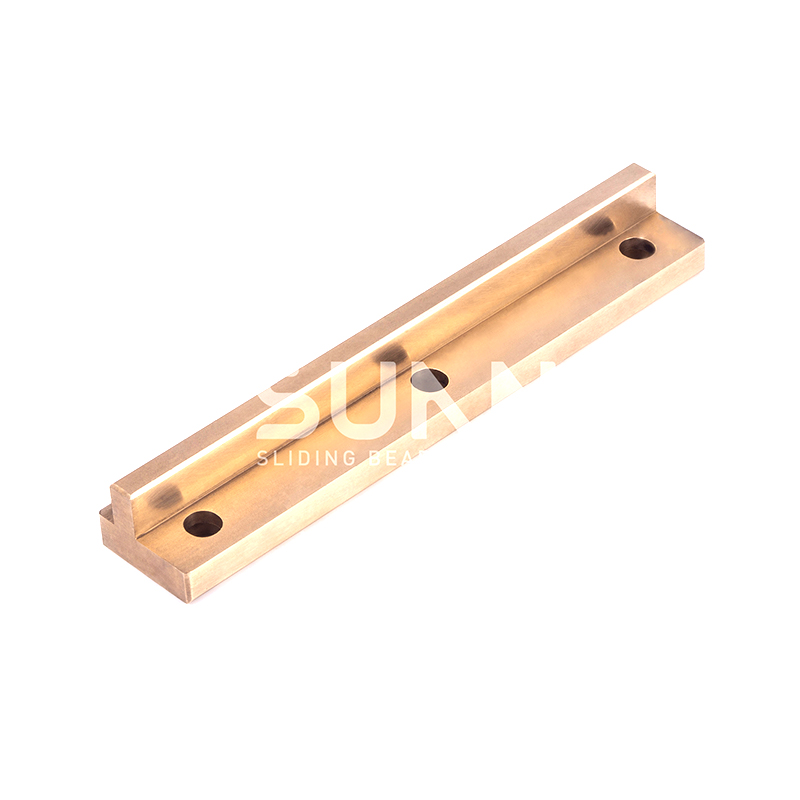

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components

JDB Solid-lubricating Bearing JSOL Embedded Bronze Oilless Wear Plate For Standard Components -

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing

JDB Solid-lubricating Bearing JDB-5 Steel Embedded Wear Resistant Solid-lubricating Bearing -

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing -

FB090 Bronze Wrapped Bearing FB090 Bronze Wrapped Bearing | Self-Lubricating Bushing & Sleeve

FB090 Bronze Wrapped Bearing FB090 Bronze Wrapped Bearing | Self-Lubricating Bushing & Sleeve -

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing

FB090 Bronze Wrapped Bearing FB092 Bronze Wrapped Bearing - Oilless Dry Sliding Bushing Self-Lubricating Bushing -

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

How to improve mechanical efficiency? What is the role of oil retained bimetal bearings in high load applications?

Industry News-In many high-load applications, mechanical equipment faces extreme wear and friction problems, and these factors not only affect the performance of the equipment, but may also shorten its service life. In order to meet these challenges, oil-retaining bimetallic bearings (Oil-retaining Bimetallic Bearings), as an advanced bearing technology, have been widely used in mechanical equipment under high load conditions. Here are the key roles oil-retained bimetallic bearings play in improving machine efficiency:

1. Reduce friction and wear

Oil-retained bimetal bearings effectively reduce the direct contact between metals by maintaining a certain lubricating oil film on the friction surface, thereby significantly reducing the friction coefficient. This oil film can effectively slow down wear, reduce friction heat during operation, and avoid overheating problems, thereby improving the efficiency and reliability of the equipment.

2. Improve load carrying capacity

Compared with traditional single-metal bearings, oil-retaining bimetal bearings usually adopt a composite structure of two different materials, in which one layer of metal has excellent pressure resistance and wear resistance, and the other layer has good lubrication retention capabilities. This double-layer structure is able to withstand higher loads and pressures, especially under high-load operation, ensuring stable operation of the bearings without excessive wear or failure.

3. Extend service life

Oil-retained bimetal bearings are designed to reduce heat generated by friction and maintain adequate lubrication during operation to prevent dry wear. As a result, the service life of the equipment is extended, maintenance costs are reduced, and downtime due to bearing damage is reduced, further improving mechanical efficiency.

4. Improve the working environment

In many industrial applications, the operating environment may include extreme conditions such as high temperature, high humidity or high pollution. The grease retention technology of oil-retaining bimetal bearings can provide continuous lubrication protection in these environments. This allows mechanical equipment to maintain stable operation in harsh environments and reduces efficiency fluctuations caused by environmental factors.

5. Reduce energy consumption

Due to reduced friction and wear, oil-retained bimetal bearings can reduce energy losses between mechanical components and reduce the consumption of electricity or other energy. This can not only effectively improve mechanical efficiency, but also save energy costs for enterprises, meeting the requirements of modern industry for energy conservation and consumption reduction.

Oil-retained bimetal bearings have significant performance advantages in high-load applications, especially in reducing friction, improving load-carrying capacity, and extending service life.