-

JDB Solid-lubricating Bearing High Temperature Brass JGB Oilless Ejector Guide Bearings

JDB Solid-lubricating Bearing High Temperature Brass JGB Oilless Ejector Guide Bearings -

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing

Oil-retaining Bimetallic Bearing Wear-Resistant Self-Lubricating Oil-Embedded 200#F Flanged Bearing -

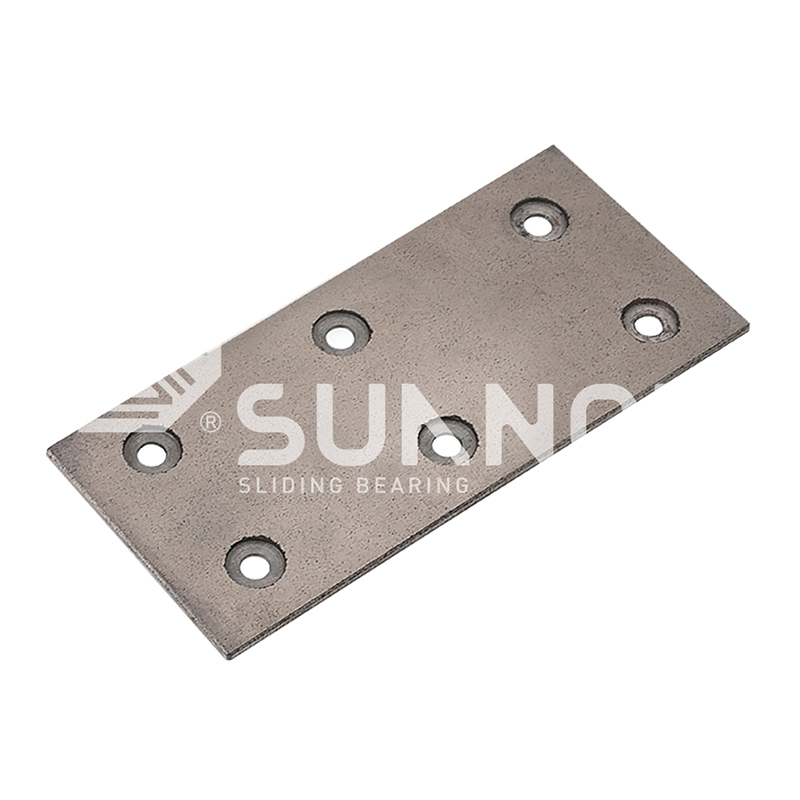

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface

Oil-retaining Bimetallic Bearing 200#P5 Self-Lubricating Oil-Retaining Wear Plate – Low Friction Bearing Surface -

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing

SF-1 Oilless Bearing SF-1P Reciprocating Motion Bronze Self-Lubricating Composite Bearing Bushing -

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush

SF-2 Boundary Lubricating Bearing SF-2 Boundary Self-Lubricating Oilless Sliding Bushing Bearing, Lead-Free Boundary Bush -

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery

JF-800 Bi-metal Bearing JF-20 High-Performance Aluminum + Carbon Steel Alloy Bearing for Industrial Machinery -

-

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

FB090 Bronze Wrapped Bearing FB09G Bronze Wrapped Bearing | Industrial Bronze Wrapped Bearing Bushing

Solid-lubricated bearings vs. grease-lubricated bearings: Which is better for high-load applications?

Industry News-When choosing a lubricated bearing, the advantages and applicable scenarios of solid-lubricated bearings and grease-lubricated bearings will affect the final decision, especially in high-load applications. The following is a comparative analysis of the two:

1. Lubrication method

Solid-lubricated bearings: This type of bearing uses solid lubricants (such as graphite, molybdenum disulfide, polytetrafluoroethylene, etc.) as the lubricating medium. It does not require liquid lubricants or grease, so it can keep running without external lubrication. Solid-lubricated bearings can effectively reduce friction and wear and are suitable for high loads, low speeds, intermittent operation or occasions where lubricants cannot be added frequently.

Grease-lubricated bearings: Grease-lubricated bearings rely on grease for lubrication and can usually maintain lubrication for a long time. Grease lubrication can effectively reduce friction, but under high loads, extreme temperatures or long-term operation conditions, the effectiveness of grease may decrease, resulting in insufficient lubrication or failure.

2. High-load resistance

Solid-lubricated bearings: Solid lubricants have high compressive strength and can maintain good lubrication under high load conditions. Especially in extreme environments (such as high temperature, low temperature, and vacuum), solid-lubricated bearings tend to perform better than grease-lubricated bearings. Since solid lubricants are not easily squeezed out, they can provide continuous lubrication under high loads.

Grease-lubricated bearings: The performance of grease-lubricated bearings under high loads may be affected, especially under high temperature or extreme working conditions, where the grease may lose its lubricating function, causing bearing wear or damage. Therefore, grease-lubricated bearings are more suitable for medium-load applications or situations that require regular maintenance.

3. Adapt to extreme environments

Solid-lubricated bearings: This type of bearing is more stable in extreme environments such as high temperature, low temperature, vacuum, and radiation. For example, in high temperature environments, grease may oxidize or decompose and lose its lubricating properties, while solid lubricants can maintain stable performance.

Grease-lubricated bearings: Grease-lubricated bearings usually have a narrow operating temperature range, and excessively high or low temperatures will cause the grease performance to deteriorate. Especially in vacuum or high temperature environments, the lubrication effect of grease-lubricated bearings may not be guaranteed.

4. Maintenance requirements

Solid-lubricated bearings: Since no grease or liquid lubrication is required, solid-lubricated bearings have relatively low maintenance requirements and are suitable for equipment that is difficult to access or cannot be maintained frequently. They can operate for a long time without regular refueling or lubricant replacement.

Grease lubricated bearings: Grease lubricated bearings need to check the grease status regularly, especially under high load, and need to keep the grease sufficient and clean to ensure good lubrication.

5. Application scenarios

Solid lubricated bearings: More suitable for applications under high load, low speed, intermittent or extreme working conditions. For example, aerospace, vacuum equipment, mechanical equipment in extremely cold or high temperature environments.

Grease lubricated bearings: Suitable for general industrial environments, especially equipment with low loads and frequent inspections and maintenance, such as some common industrial machinery and automobiles.