-

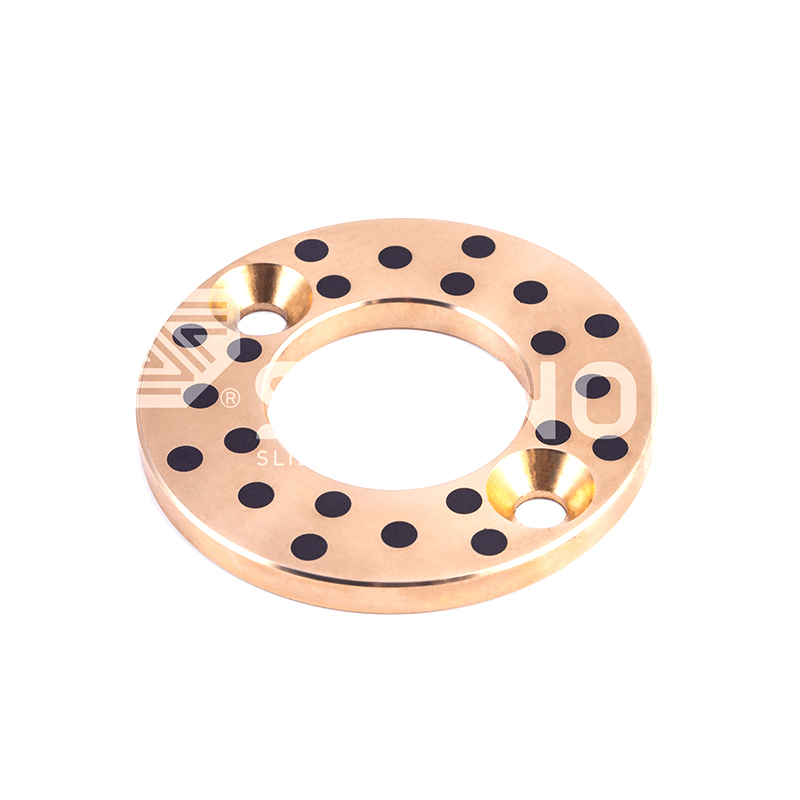

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing

JDB Solid-lubricating Bearing JTW Solid Lubricant Graphite Oilless Bronze Thrust Washer Bearing -

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing

JDB Solid-lubricating Bearing Round Self-lubricating JOST Oilless Brass Flanged Guide Bearing Bushing -

-

-

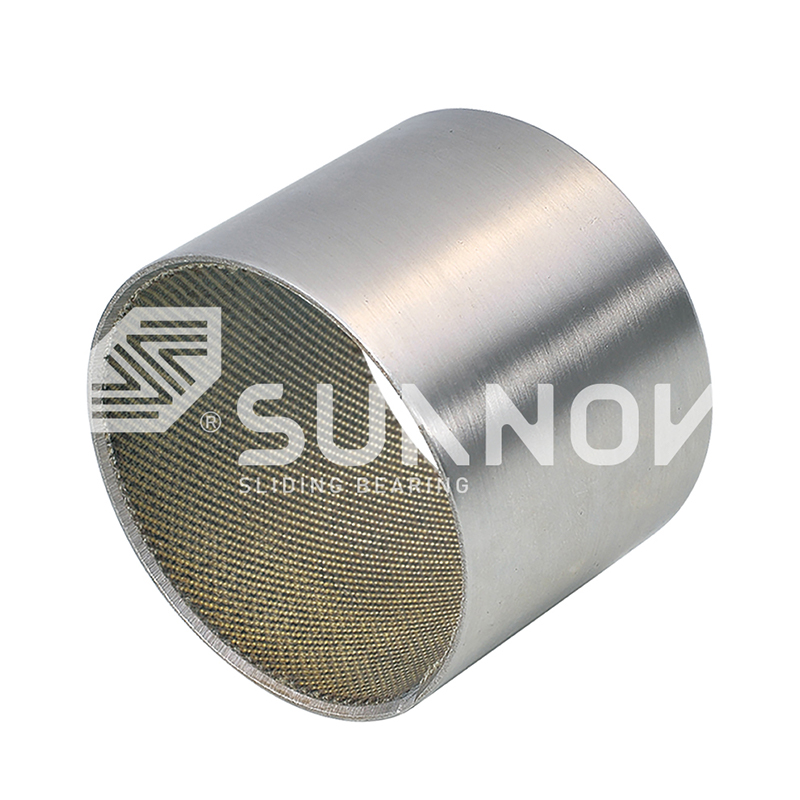

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications

JF-800 Bi-metal Bearing JF-720 Tin Bi-Metal Bearing Bushings Sleeves For Low Friction and Wear-Resistant Applications -

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction

JF-800 Bi-metal Bearing JF-750 Self-Lubricating Lead Free Bi-Metal Bearing for Heavy Duty Engines Low Friction -

FB090 Bronze Wrapped Bearing FB091 High-Performance Copper Wrapped Bearing & Bushing | Bronze Bush

FB090 Bronze Wrapped Bearing FB091 High-Performance Copper Wrapped Bearing & Bushing | Bronze Bush -

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

FB090 Bronze Wrapped Bearing FB094 Bronze Wrapped Bearing: Lead-free, High Load Capacity, Self-lubricating

How do self-lubricating copper alloy bearings perform in extreme working environments?

Industry News-Self-lubricating copper alloy bearings generally perform very well in extreme working environments, especially under conditions of high temperature, high load, corrosive environment and high friction. The following are the key advantages of self-lubricating copper alloy bearings in these conditions:

1. High temperature resistance

Self-lubricating copper alloy bearings have excellent high temperature resistance and can operate stably in environments with temperatures up to 300°C or even higher. This makes them very suitable for use in high-temperature industrial environments, such as metallurgy, petrochemical and steel production. The good thermal conductivity of copper alloys helps to disperse heat and reduce temperature damage to bearings.

2. Reduced wear and improved corrosion resistance

Due to the inclusion of solid lubricants (such as graphite or friction modifiers), self-lubricating copper alloy bearings can effectively reduce the coefficient of friction and wear without external lubricants. This makes them particularly good in environments without continuous manual lubrication or in difficult lubrication environments (such as places with bad weather, moisture, and highly corrosive liquids).

3. Corrosion resistance

Copper alloys themselves have strong corrosion resistance, especially in highly corrosive application scenarios such as marine environments and chemical processing plants. When used in these extreme environments, self-lubricating copper alloy bearings not only maintain their structural integrity, but also reduce bearing failure or malfunction due to corrosion.

4. Withstand high loads

Self-lubricating copper alloy bearings can withstand large loads, especially when heavy equipment or machines are running, and can effectively disperse the pressure on the bearings. This makes them particularly suitable for high-load demanding occasions such as heavy machinery, mining equipment and aerospace.

5. Low maintenance requirements

Since self-lubricating copper alloy bearings have built-in solid lubricants, they do not require frequent refueling or lubricant changes during operation. Compared with traditional bearings, this greatly reduces the frequency of maintenance and reduces equipment downtime, especially for extreme working conditions where long-term operation is difficult to frequently inspect and maintain.

6. Self-lubricating properties reduce wear

Even under extremely high loads and high speeds, the lubricating layer of self-lubricating copper alloy bearings can form a self-repairing lubricating film on the surface, thereby reducing the lubrication effect that is difficult to achieve with traditional lubrication systems. This allows them to work effectively under extreme friction conditions.