Zhejiang Shuangnuo Bearing Technology Co., Ltd.

Zhejiang Shuangnuo Bearing Technology Co., Ltd. is

China 200#P5 Wear Plate Suppliers and

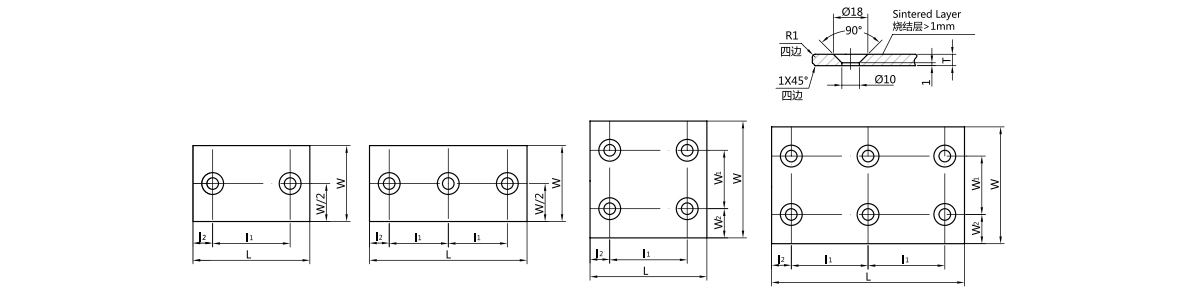

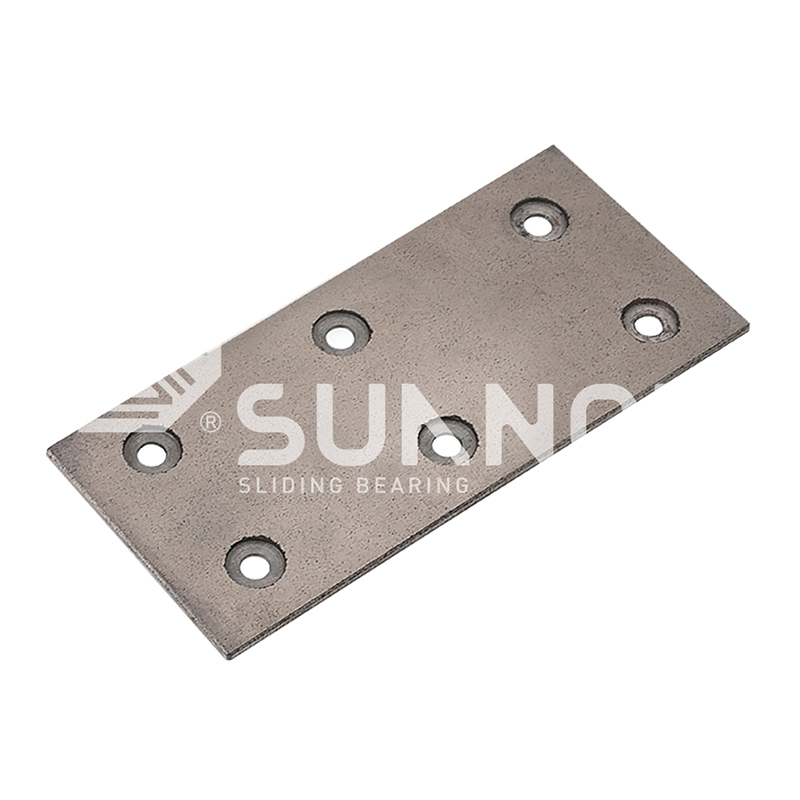

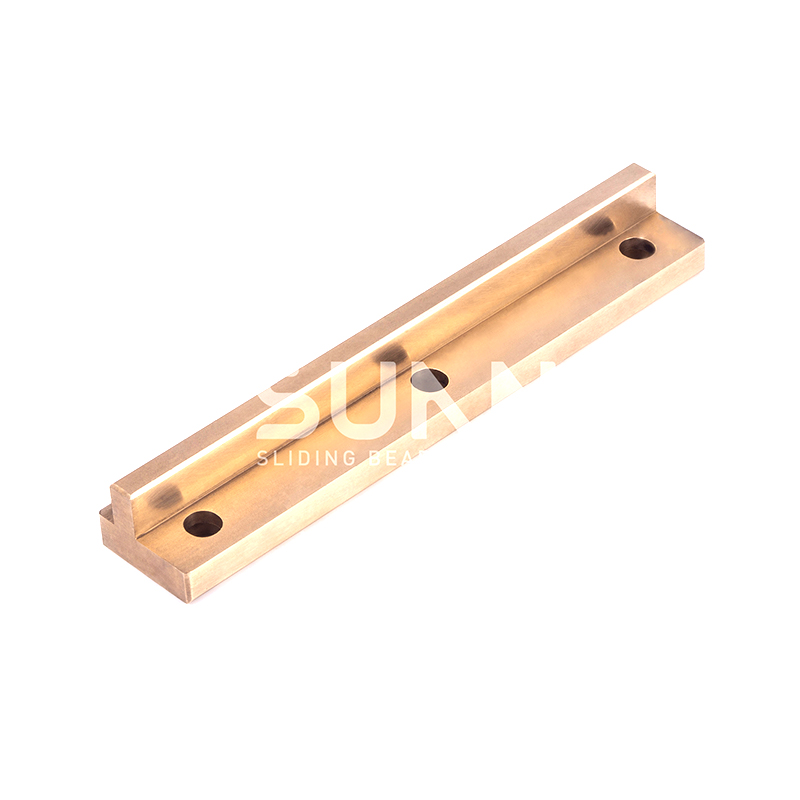

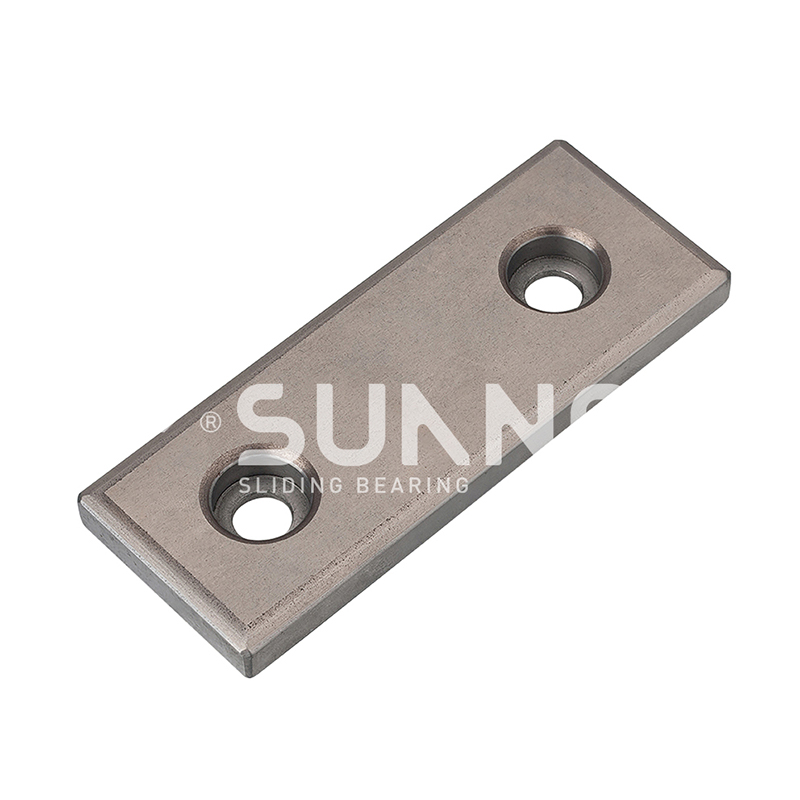

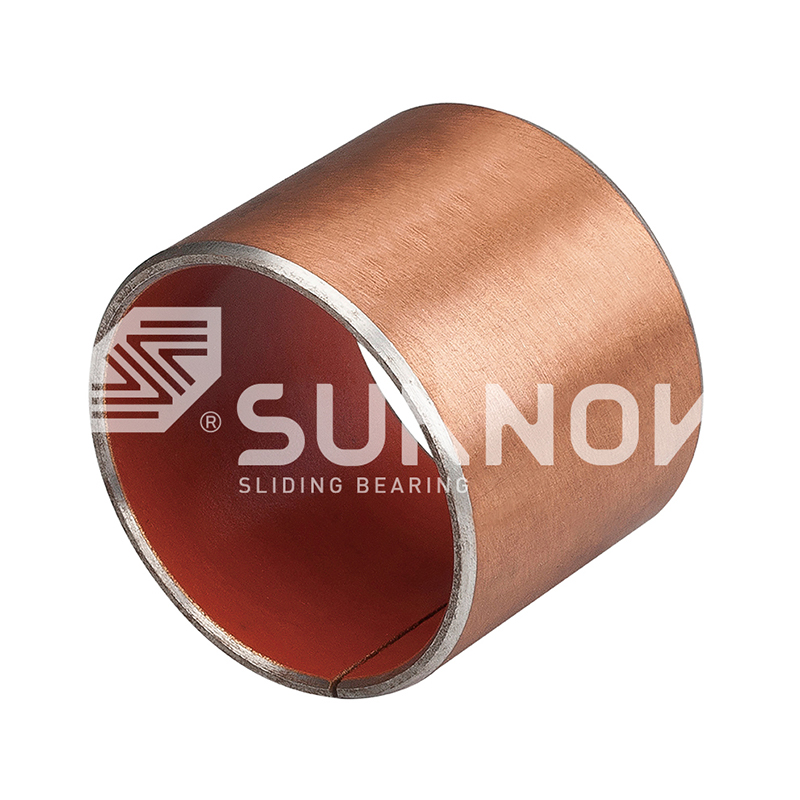

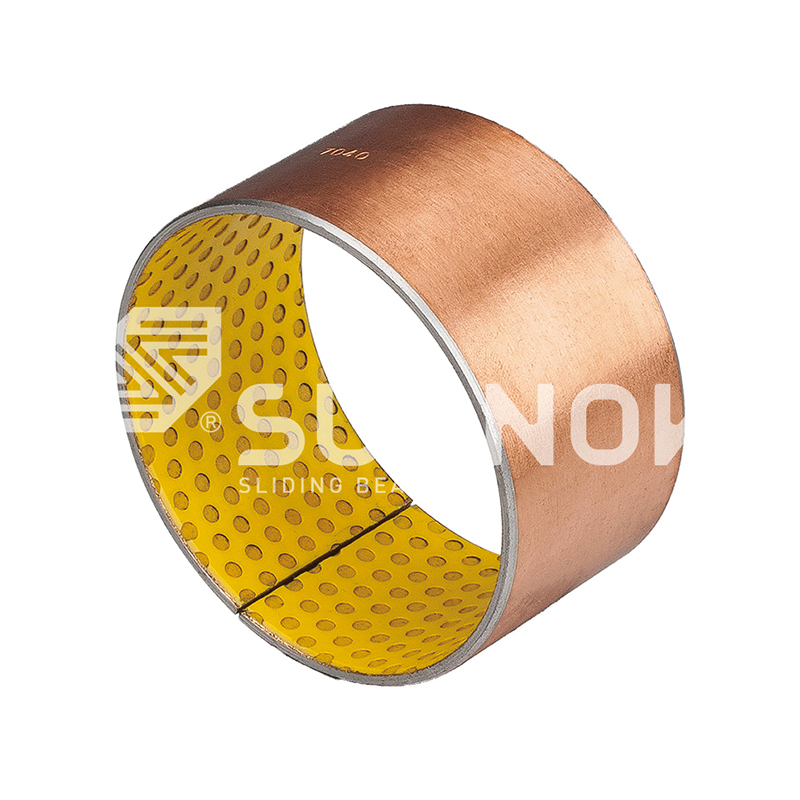

Wholesale 200#P5 Wear Plate Company, we are a manufacturer specializing in producing various self-lubricating copper alloy products using centrifugal casting, continuous casting, metal mold casting, and other processes. Its main products include brass, aluminum bronze, tin bronze, and others produced according to national standard grades. It processes and produces various solid inlaid self-lubricating bearing products on this basis

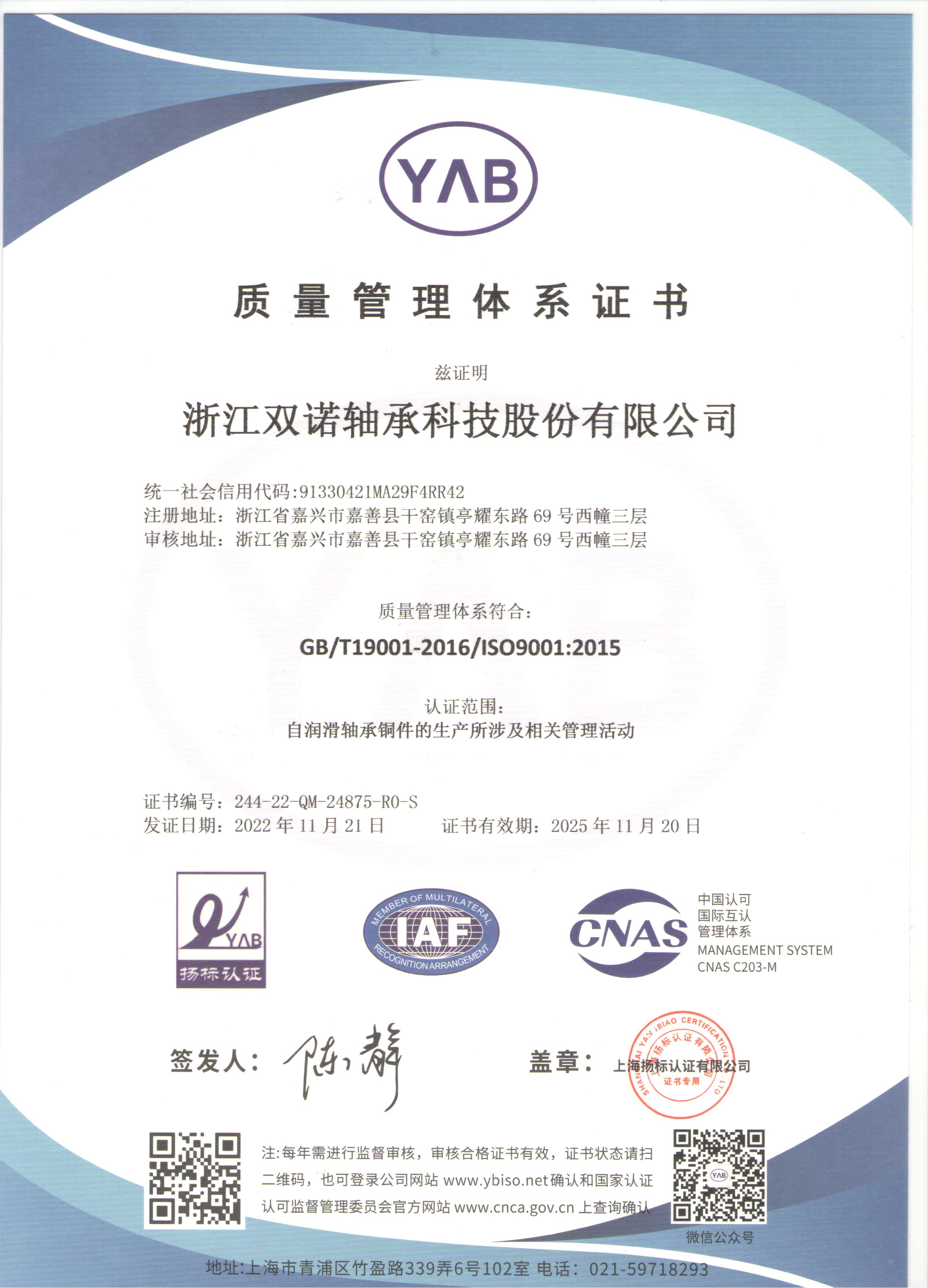

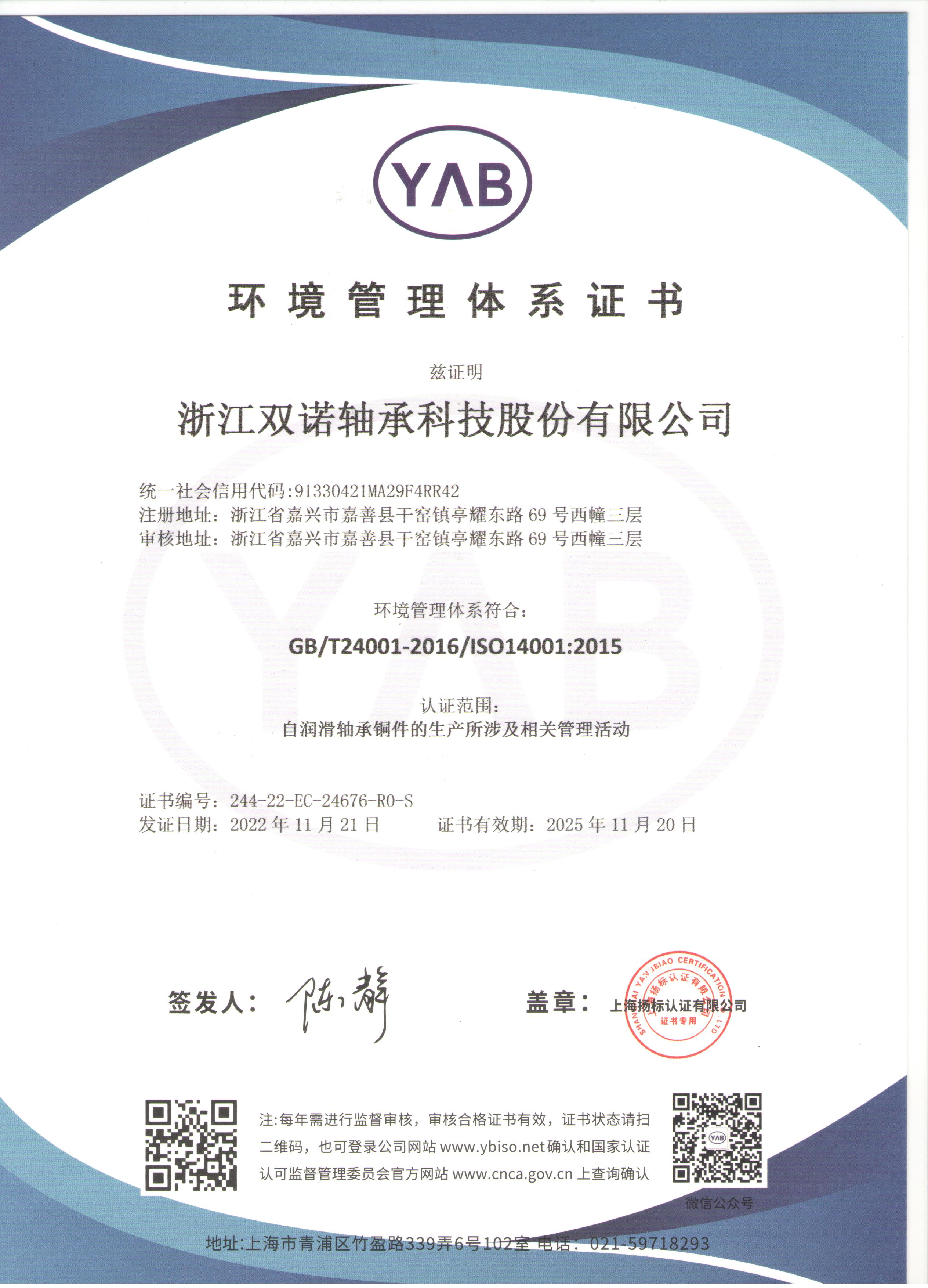

. At the same time, it uses sintering technology to produce bimetallic products and many other types of products. Since its establishment nearly 10 years ago, the company has focused on the research development, and production of various new self-lubricating bearings.

In the process of product production, our company has always insisted on independent casting production of raw materials to ensure the quality of products from the source; during the casting process, the whole process is monitored, and the finished product is tested by spectrometer three times before, in and after the furnace to confirm the material composition of the product. The national testing agency is regularly commissioned to test the material composition and mechanical properties of the product, and authoritative test reports can be provided to customers in need; the company implements integrated production from material to finished product processing and has more than 80 sets of advanced CNC machine tools, CNC lathes, machining centers, and other major equipment. The strong production capacity ensures that the material production is organized for customers for the first time, shortening the production cycle.